Regulatory developments in the sustainability of business activity in Europe will have a significant impact on suppliers of parts and components in the automotive value chain. The automotive supply chain will have to incorporate management tools to obtain environmental product footprints.

Regulatory framework

On 28 March 2023, the Council of the EU adopted the regulationwhich is part of the package Fit for 55setting stricter CO2 emission standards for new passenger cars and vans. The regulation includes a provision for the development, by 2025, of a common EU methodology for assessing the full life-cycle CO2 emissions of cars and vans placed on the EU market, which should cover the production phase and include the manufacture of components.

On the other hand, the directives on corporate sustainability, (CSRD) y (CSDDD) require large companies to disclose, at a high level of detail, their policies and concrete measures in relation to climate change. This includes carbon footprint management measures throughout their value chain, with a significant impact on the supply chain of large manufacturing companies. Therefore, participants in the supply chain of large manufacturers will have to provide information on the carbon footprint of their products.

Car manufacturers will have to assess the entire life cycle of cars and vans, including the manufacture of components.

The life cycle of a car

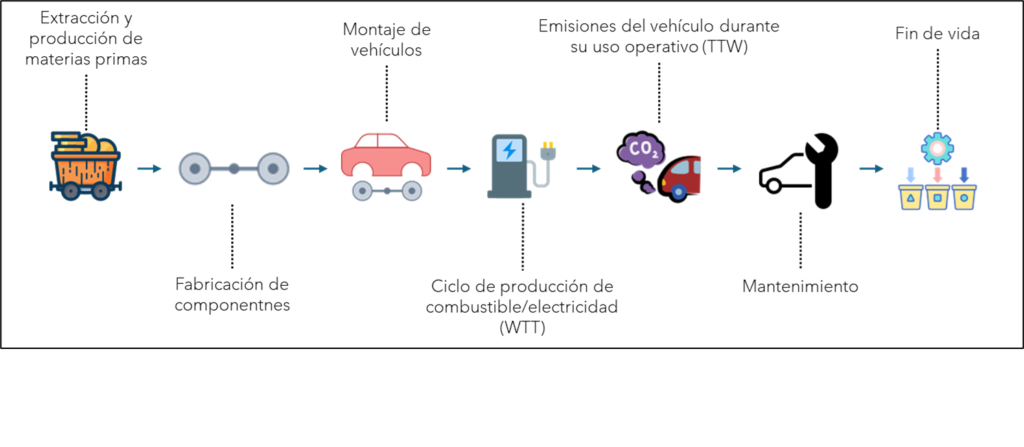

The complete life cycle of a vehicle comprises the stages of:

- Production: production of raw materials, manufacture of components and assembly of vehicles

- Well to Tank (WTT): fuel/electricity production cycle

- Tank to Wheel (TTW): impacts due to vehicle emissions during operational use

- Maintenanceimpacts of spare parts and consumables

- End of lifeimpacts/credits of collection, recycling, energy recovery and disposal of vehicles and batteries

Diagram of the complete life cycle of a car. Source: own elaboration

The challenge for TIERs

In order to be able to measure the emissions of the production stage, car manufacturers will need to have the environmental footprints of the components and therefore request it from their suppliers. This is a major challenge for TIERs, which will have to establish procedures and tools and allocate resources to the calculation of the product carbon footprint.

In practice, there are two opposing approaches to managing the product carbon footprint in the TIERs, with intermediate gradations in between:

Outsource the environmental footprint measurement process: In this approach, the manufacturing company outsources the environmental assessment to a specialised Life Cycle Assessment (LCA) consultancy. This is often the preferred option for the first experience with LCA and for acquiring a first set of knowledge and skills. Collaboration with a specialised consultancy facilitates the understanding of the methodology and management processes.

Internalise the environmental footprint measurement process: In this approach, the manufacturing company undertakes the environmental assessment of its product portfolio internally. This option is usually considered after having worked with a consultancy and having a sufficient knowledge base. It can also be considered from the outset. Internalising the measurement of product environmental footprints involves the integration of calculation tools (generic LCA software or ad-hoc designed calculation tools) and the availability of professionals with specific training in LCA.